Climate change is the result of increasing greenhouse gasses and carbon emissions. Buildings generate nearly 40% of those emissions. The measurement of these greenhouse gasses and carbon emissions determine a building’s carbon footprint. As architects and engineers, we have the ability to affect climate change by how we design and construct buildings. The best way to determine how well we are preventing climate change is by reducing the carbon footprint of our buildings.

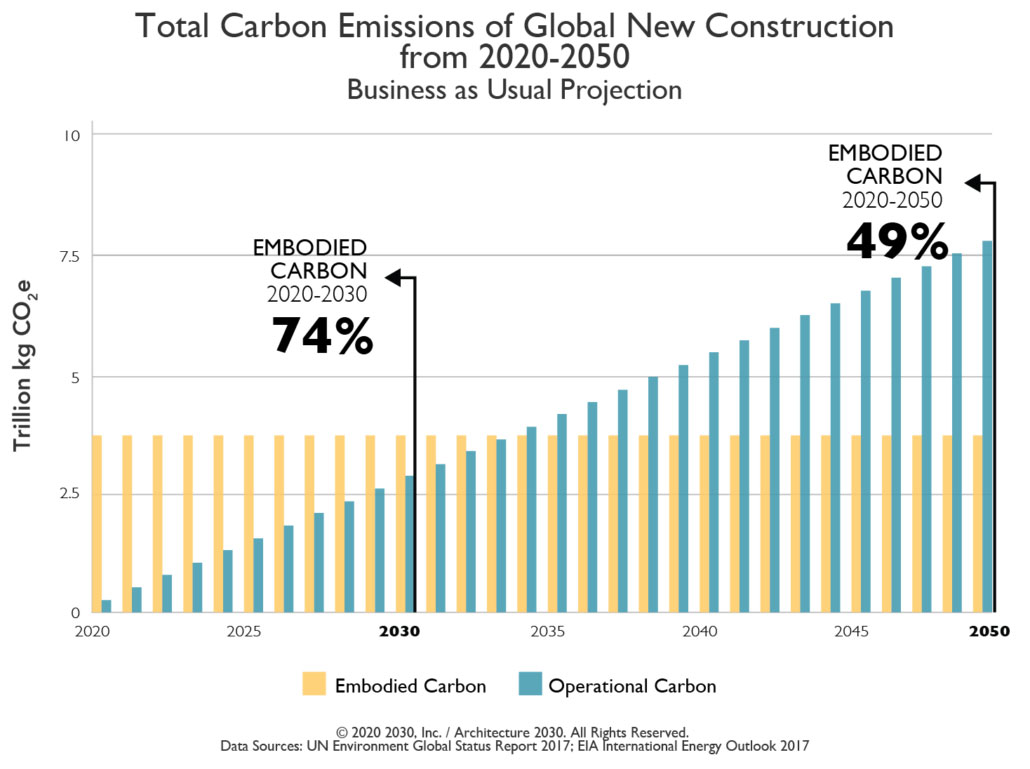

The two ways buildings generate greenhouse gasses and carbon emissions is through building operations and embodied carbon. 72% of a building’s carbon footprint is due to building operations, and the remaining 28% is due to embodied carbon. Building operations generally refers to energy consumption, while embodied carbon relates to how the building materials are created.

Energy Use:

Reducing energy use is the easiest method of reducing a building’s carbon footprint. At least, it is easier to track. Coal fired power plants are some of the highest producers of greenhouse gasses while solar, wind, and other renewable power sources are the lowest producers of greenhouse gasses. As a result, public utilities are closing coal fired power plants and replacing them with solar and wind farms. At the building level, installing solar panels or purchasing green power credits are the most obvious strategies to reduce a building’s carbon footprint. Other strategies utilized that dramatically affect a building’s energy use include increasing insulation values above code minimum, high-performing glazing, and continuous air barriers.

The optimal values of insulation and glazing can be found by utilizing energy modeling. You can put 12” of insulation and triple glazing, but the energy improvements between 8” and 12” of insulation may not justify the additional costs. Also, beware of the law of diminishing returns.

Embodied Carbon:

Embodied carbon is the amount of carbon used to extract, manufacture, and transport building materials. This can be challenging, and the right answer is not always obvious.

To begin, start with the highest cost items – the building structure and envelope. Fortunately, structural materials, determining the carbon footprint can be easy to measure. Wood, steel, and concrete have dramatically different carbon footprints, but are easy to measure. While building envelope items can be tougher. While some building skin items can be easy, other items, like insulation, can be much tougher.

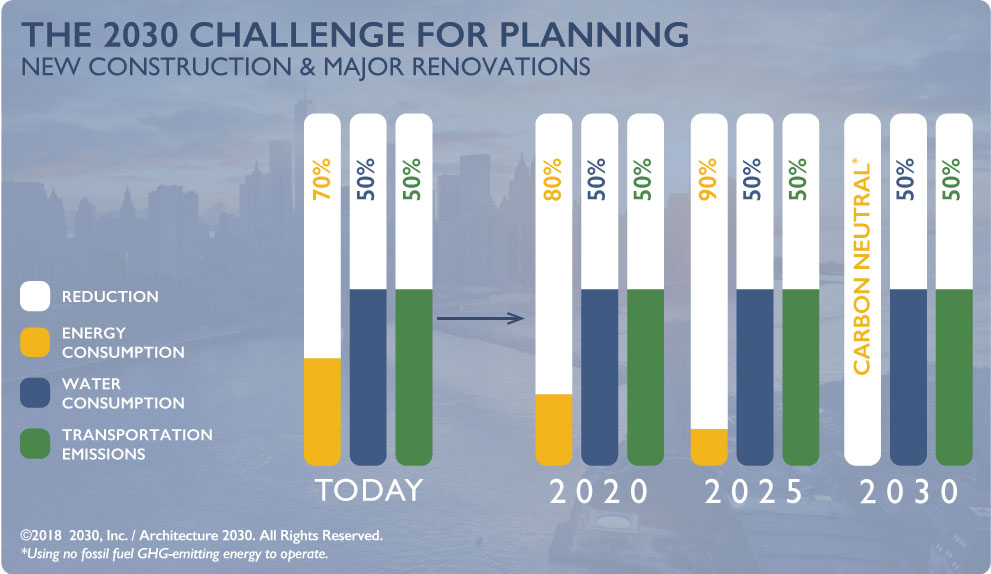

Fortunately, there are resources available to determine the embodied carbon. The best resource for architects is Architecture2030.org. Architecture 2030 was created by Ed Mazria to challenge architects and engineers to reduce carbon emissions, and his efforts have been well received within the design community.

In conclusion, the best advice for reducing a building’s carbon footprint is to do everything you can, know that more can be done, but keep pushing yourself and those around you. Although challenging, we need to achieve zero-carbon buildings in order to reduce climate change, and this is the path that we all have to take.

Featured Author: JoAnn Brookes, AIA, LEED AP BD+C

Senior Associate, PERKINS EASTMAN

San Francisco, CA, US

The Lumiflon guest blog posts feature industry professionals sharing their expertise across a broad range of topics. Lumiflon is a solvent-soluble fluoropolymer for coatings developed in 1982. Fluoropolymer coatings based on LUMIFLON have been produced by many coating manufacturers worldwide. These coatings maintain gloss and color when applied to buildings, bridges, water towers, aircraft, automobiles, and other structures for well over 20 years. They also protect steel, aluminum, fiberglass, concrete, and other materials of construction from corrosion, sunshine, wind, and rain. The use of LUMIFLON resins can substantially reduce life cycle costs, including maintenance cost, replacement cost, and re-coating costs, providing it a sustainable alternative to other coatings systems.