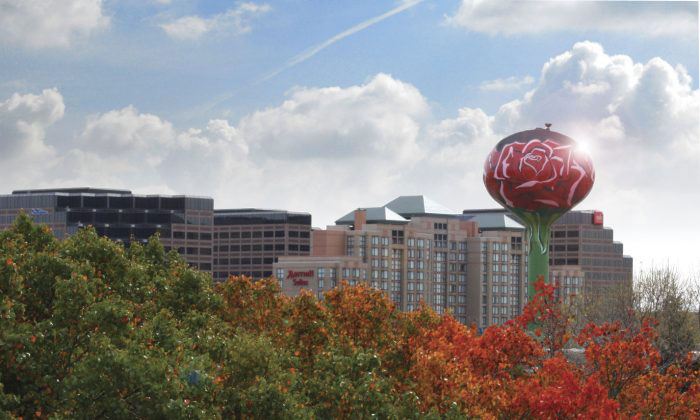

The Rosemont, IL water tower was completed in late 2006 and was the first winner of Tnemec Company’s coveted Tank of the Year Competition. The intricately-rose-painted tank has been a village landmark since its construction in 1982. Since then, the water tower has undergone two significant repaints utilizing an oil-based enamel paint in 1990 and 1998. When recoating was necessary again in 2006, Christopher Burke Engineering and the Village of Rosemont, Illinois, chose a long-lasting, durable Tnemec coating.

Field Applicator Jetco, Ltd. Representative Kenneth Brend described, “The rose pattern required six different colors, so we had to apply them in two different layers. So we went around the whole tower once applying half the colors, then came back again and finished the design.”

© Epoch Times Photograph

The project took six months to complete and required a specialty containment system to prevent dust from escaping the job site and disturbing nearby businesses.

Representatives at Tnemec Company explained, “Brend duplicated the original rose design by sketching it in pencil directly onto the tower using photographs as a reference. Then, he spent several weeks applying the finish coat of Series 700 HydroFlon, a two-component, fluoropolymer polyurethane chosen for its superior long-term gloss and color retention as well as its life expectancy.”

©Journal Topics Photograph

The exterior design took nearly 100 days to finish, with wind and rain causing delays throughout. However, Brend explained that when the project reached completion, the public was enthused with the result, describing, “The Rosemont public works department received numerous phone calls from people stating how beautiful it looked. Everybody loved it.”

The HydroFlon fluoropolymer finish ensures long-lasting gloss and color retention. This next-generation, high-performance fluoropolymer contains Lumiflon FEVE technology, which is the main contributor to the coating system’s hyper-durability. In addition, Lumiflon FEVE resin protects water tank surfaces, helping prevent coating degradation at the hands of UV radiation, salt, and water. FEVE-based coatings also offer superior color and gloss retention and anti-corrosion properties that maintain the coating’s structural integrity.

Photography ©see below each image

Categories Water Tanks/Infrastructure