Architectural coatings are applied to commercial, office, retail, educational, stadiums and residential buildings for both decorative and protective purposes. These coatings enhance the aesthetic appeal of structures with a variety of colors, textures and finishes, while also providing weather resistance, corrosion prevention and long-term durability. These attributes help buildings withstand harsh environmental conditions while maintaining their visual appeal.

LUMIFLON® FEVE resins are widely used in architectural coatings to protect metal, and other sub-structures from degradation driven by UV light, wind, rain and corrosion. Based on an advanced fluoroethylene vinyl ether (FEVE) chemistry, these resins enact high-performance coatings well-known for their outstanding weatherability/durability, UV and chemical resistance and long-term gloss and color retention.

FEVE resins are transparent, allowing them to be formulated into both clear and pigmented coatings. They are available in well over 230 colors and a full range of gloss levels, from high gloss to matte finishes. Based on their exceptional weathering properties, FEVE-based coatings maintain their vibrancy and aesthetics for 20 to 60 years. This durability means that structures can be repainted less frequently, extending maintenance times. When factoring in maintenance, recoating and replacement costs, these resins provide substantial life cycle cost savings compared to traditional coatings.

Versatile Formulations for Diverse Applications

FEVE resins come in different grades, providing formulators flexibility for different types of coatings, such as solvent-based, water-based, and high-solid systems. The grades vary in molecular weights, functionality and provide options that are solvent-, solid- or water-based, allowing formulators to meet specific performance and environmental standards. For instance, solid resins are especially suitable for low-VOC and HAPs-free applications.

Solvent-Based Resins: Maximum Durability and Aesthetics

These ultra-weatherable and highly durable FEVE resins offer protection against extreme environmental conditions, keeping coatings vibrant and glossy for decades. Coatings formulated with solvent-grade LUMIFLON resins such as LF552E and LF910LM allow the use of brighter more vibrant colors and higher gloss, achieving gloss values as high as 90. The FEVE based coatings perform well on various substrates, including steel, aluminum, fiberglass composites, concrete and polycarbonates, demonstrating its integrity for 30 years or more without fading.

Solvent-based grades can be cured under ambient or thermal conditions, making them suitable for field applied recoating of structures or fabrication of pre-coated panels in the shop environment. They are especially ideal for spray applications and are commonly used as the topcoat in two-component systems or three-component systems that employ epoxy or urethane mid or base coatings.

Solid-Based Resins: Low-VOC, Environmentally Friendly Solutions

These environmentally friendly solid resins contain no solvent compounds and support low-VOC (volatile organic compounds) or zero-VOC coating systems, giving formulators flexibility to select applicable low or no VOC formulations. With 100% resin content, they comply with stringent air pollution regulations by minimizing VOC emissions, which helps meet solvent usage regulations in various countries.

LUMIFLON LF200F and LF916F solid grades offer excellent weather resistance and heavy-duty corrosion protection. They can be blended with various solvents to create low-VOC and HAPS-free coatings without compromising performance, providing an eco-friendly option for regulatory compliance.

Power Resins

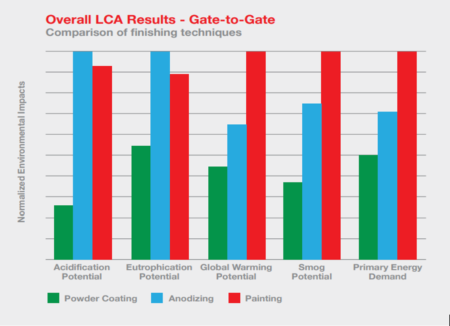

LUMIFLON solid-based resins are also available as powders, presenting a sustainable option with a smaller carbon footprint, as they do not rely on VOCs for processing and application. With superior weather resistance, LUMIFLON LF710F powder resins reduce the need for recoating, extending the timeline between maintenance and lowering the operational carbon footprint impact of a project. Studies have shown that these resin powder coatings can achieve a carbon footprint reduction of 23% to 46% compared to traditional solvent-based coatings.

Delivered electrostatically without VOCs, they eliminate the need for chrome-based primers on aluminum systems. This innovation helps reduce coating waste and water consumption during the coating process. The powder coating method ensures very high coating transfer efficiency and optimal material usage. With their superior performance and sustainability, FEVE-based powder coatings are an ideal choice for eco-friendly, super-durable finishes.

Water-Based Resins: Low Impact, High Performance

LUMIFLON water-based resins such as FE4400 and FD1000 offer strong coating performance and outstanding exterior durability while reducing VOCs. They are non-flammable and produce less odors, minimizing environment impacts at painting sites. These emulsions serve as solvent-free alternatives to conventional fluororesins and are suitable for single or two-component coatings.

Particularly beneficial for architectural restorations, these resins can be applied in the field and cure at ambient temperatures. Different grades are available for formulating water-based 1K and 2K polyfluorourethane coatings with excellent aesthetics and durability.

Source: LUMIFLON brochure

FEVE-based coatings help buildings qualify for LEED credits

FEVE resin-based coatings offer a sustainable, high-performance solution for environmentally conscious architectural projects. These coatings can contribute to Leadership in Energy and Environmental Design (LEED) certification, which is the world’s most widely used green building rating system and a globally-recognized symbol of sustainability achievement.

FEVE coatings help support LEED credit eligibility across multiple categories:

- Materials and Resources: FEVE-based systems provide exceptional durability, outlasting conventional coatings. This longevity reduces the frequently of recoating and extends the maintenance cycle, resulting in less material consumption and a lower environment footprint over the building’s lifecycle.

- Sustainable Sites: Emulsion-based FEVE coatings help maintain solar reflectivity, reducing heat island effects and improving the quality of stormwater runoff from roof surfaces.

- Energy and Atmosphere: By maintaining performance in extreme weather conditions, FEVE reduce heat transfer through roofs and curtain walls. This helps lower indoor cooling loads and supports energy efficiency over time.

- Innovation: LUMIFLON FEVE resins and available functionality, offer a variety and range of options for architectural coatings. Their durable, low-VOC formulations promote environmental responsibility while offering flexibility in design and provides exceptional performance.

Furthermore, since FEVE resins provide a wide range of required performance features, they can be formulated to meet stringent AAMA 2605 requirements, which is the American Architectural Manufacturers Association’s specification standards for high-performance exterior architectural coatings.

Notable LEED Projects

LUMIFLON FEVE has been selected for some of the world’s most iconic and environmentally responsible structures, due to their durability, weatherability and compliance with green building standards.

Aldar Corporate Headquarters, Abu Dhabi, UAE

A 23- story corporate designed in accordance with the US Green Building Council LEED rating system uses a custom FEVE coating blend, contributing the energy efficiency and environmental performance.

San Diego International Airport

Achieving LEED Platinum, the airport incorporates a low-VOC LUMIFLON-based coating system on all exterior exposed steel surfaces, including two sky bridges and canopies.

Manitoba Hydro – Winnipeg Canada

Canada’s first LEED Platinum-certified office tower features 32,5000 square feet of aluminum composite panels coated with LUMIFLON FEVE. The coating contributes to thermal efficiency, long-term durability and reduced maintenance.

AGC works closely with coating formulators to identify the ideal LUMIFON grade for each project. Whether the goal is to maximize weatherability, enhanced application efficiency or meet sustainability standards, AGC provides the technical expertise needed to ensure optimal results.

Contact us at 800-424-7833 for more information on the latest innovations related to LUMIFLON FEVE resins.

Photo credits: Aldar, Gensler and Manitoba Hydro.