LUMIFLON® Technical Bulletin: (Download as a PDF)

LUMIFLON is a fluoropolymer resin composed of alternating fluoroethylene and vinyl ether segments (FEVE). Polymers with this unique chemical structure produce coating formulations with exceptional durability, weatherability, and chemical resistance.

In the U.S., coating systems are priced in $/gallon. However coating cost per gallon or coating cost per surface area is not a true measure of the value of a coating system. Life cycle cost (or the applied cost) which takes into account not only coating costs but application costs, labor, and staging costs is the most accurate way to measure the cost of a coating system.

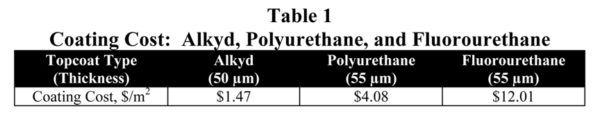

When measured by conventional pricing methods LUMIFLON based coatings appear to be more expensive than most other coatings due to the higher cost of the resins. As Table 1 illustrates, LUMIFLON is eight times the cost of the alkyd topcoat, and almost four times the cost of the polyurethane. According to Table 1, it appears that the fluorourethane is the least cost effective coating system analyzed, but this isn’t accurate.

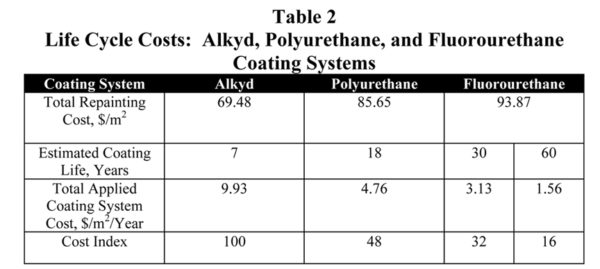

The proper method of developing costs for coating systems is to use life cycle costs; that is, the applied cost of the entire coating system per year of coating life. Table 2 shows the comparative life cycle costs for an alkyd, polyurethane, and a fluorinated urethane and proves that the LUMIFLON based fluorourethane is actually the most cost effective product.

Coating specification from “Coating Handbook for Steel Bridges,” Japanese Road Association. Other references include “Civil Engineering Cost Information” July, 2006, “Prices of Construction Materials and Wages” October 2006, and “Heavy Duty Construction Guidebook” March 2007. Repainting cost includes cost of primer, middle coat, and topcoat, labor, surface preparation and staging costs. Total coating thickness used varies based on relevant specifications.

Table 2 includes several pieces of important information. First, the applied cost range of the coating systems tested is far narrower than the cost of each topcoat. Based on the cost of the alkyd coating system, applied cost for the LUMIFLON based fluorourethane is only about 35% higher. This is because for almost any industrial painting project, labor costs, application costs and staging costs are higher than the coating system cost. Compared to the polyurethane system, the LUMIFLON system is only about 10% higher in cost. Both of these systems used similar primers (zinc rich) and middle coats (epoxy), so the difference in applied cost is due to the higher price of the fluorourethane.

Total applied cost is the applied cost of each coating system divided by the years of expected service. When this measure is used, the life cycle cost of the LUMIFLON based coating system is only 1/3 that of the alkyd, and only 2/3 the cost of the urethane assuming a topcoat life of 30 years. If the fluorourethane topcoat life is assumed to be 60 years, then the relative cost falls again. When coating life is taken into account, the LUMIFLON based coating system is by far the most cost effective.

Download this Technical Bulletin as a PDF: Technical Bulletin-Life Cycle Cost Analysis

Disclaimer: The information given in this post is for information purposes only. It is given in good faith and based on the best knowledge and experience of the company. This product should be used only in applications for which it was intended. This product is not designed for special applications such as pharmaceutical or other medical use. The company makes no warranties and undertakes no responsibilities regarding this product except as stated in contract documents for its supply.

Please send me a binder with color chips. Paper copy if available.

850 2nd. Street, Unit 315

Santa Monica, CA 90403