Green construction aims to reduce the environmental effects of building. Its prevalence today is widespread as the need for sustainable alternatives continues to increase. Green building encompasses the entire construction process from inception to construction to eventual demolition, and includes building products, functionality, and maintenance.

An important factor in the architectural and industrial building market is a structure’s need to withstand environmental degradation. Now although the weatherability of exterior products is paramount, the coatings on those products are equally important.

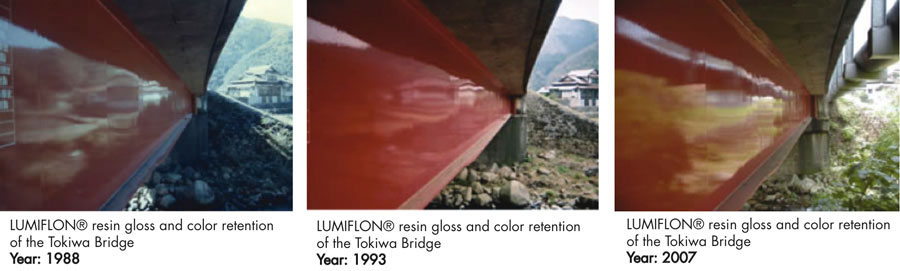

For years, architectural and industrial coatings were prone to deterioration and required high maintenance costs. Due to their tendency to fade, chalk and peel, coatings before the 1980s required continuous reapplication. The durability of a topcoat has environmental impacts in regards to production, transportation, application, installation and replacement costs.

With the need for an environmentally friendly alternative to traditional coatings, LUMIFLON resins were produced and became a leader in the market due to their long life cycle. Our topcoats can last 30 years without degradation, reducing the need for reapplication, and resulting in a more sustainable alternative. Since the greenest buildings are those that never get built, our clear topcoat can also be applied to existing structures, minimizing the need for reapplication or reconstruction.

Of the four types of LUMIFLON resins, three – solid, powder, and emulsion-grade — contain zero volatile organic compounds, meeting the most stringent green building criteria in the United States.

The benefits of green construction go beyond the environment, to the production of more economically and socially beneficial structures.