Bridges face relentless exposure to UV radiation, moisture, temperature swings and chemical attack from salts and other electrolytes. These conditions degrade protective coatings, allowing corrosion agents to migrate through the coating to attack of the metal substructure, which accelerates steel corrosion and significantly reduces service life. Choosing the right coating system is critical, not only to preserving structural integrity but also for reducing long-term maintenance costs.

LUMIFLON® FEVE (fluoroethylene vinyl ether) resins, developed in 1982 by AGC, Inc. (formerly Asahi Glass Corporation), offer a breakthrough in bridge protection. Unlike conventional epoxy and polyurethane coatings, FEVE-based systems retain surface and barrier integrity, providing unmatched weatherability, corrosion resistance and long-lasting aesthetic performance.

Why Traditional Coatings Fall Short

Conventional coatings, such as polyurethane and epoxy, have notable limitations.

- Epoxy coatings excel at adhesion and chemical resistance but deteriorate quickly under UV light.

- Polyurethane coatings offer UV resistance but have lower chemical resistance and higher material life cycle costs.

Both require frequent maintenance and recoating — disrupting traffic and driving up lifecycle costs.

The LUMIFLON Advantage

FEVE resins contain reactive components that produce fluor-urethane networks when cured and crosslinked. The precursor components are very compatible with standard solvents and can be applied with standard application equipment, such as brush, spray and roller applications.

Coatings formulated with LUMIFLON provide:

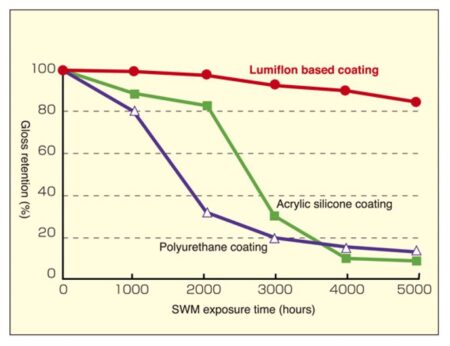

- Exceptional UV and chemical resistance, providing decades of durability with minimal fading or chalking.

- Superior corrosion protection, reducing blistering, peeling and rust formation.

- Reduced maintenance costs, including fewer recoating cycles, less labor and minimal traffic disruption.

- Environmental compliance, contributing to low-VOC and water-based formulations that meet strict regulations.

- Extended aesthetics, enabling color and gloss retention lasting 20–60 years.

Life-Cycle Cost Savings

Although FEVE topcoats can cost two to four times more than polyurethane initially, their 30- to 60-year service life dramatically lowers overall expenses. Studies show:

- 15–30% lifecycle cost savings compared to polyurethane.

- 40–80% of the total lifecycle cost of polyurethane systems, which often need two to three recoats in the same timeframe.

The result is higher ROI on infrastructure investments and reduced financial strain on municipalities.

Proven Success On Iconic Bridges

I_74 Mississippi River Bridge (Iowa/Illinois, USA)

Completed in 2021, this award-winning structure features Sherwin-Williams Fluorokem® coatings formulated with LUMIFLON. The system ensures long-term resistance to UV and moisture, cutting repainting costs and maintaining aesthetics.

Featuring durable steel arch ribs in a distinctive basket-handle configuration, the bridge was honored as a “Top Bridge of 2022” by Roads and Bridges Magazine.

This advanced coating system delivers long-lasting weather resistance and corrosion-resistance, protecting the bridge against degradation caused by UV light, wind and rain.

Florida’s Sunshine Skyway Bridge (Florida, USA)

The repainting of its iconic yellow cables used Tnemec’s Fluoronar®, powered by LUMIFLON FEVE technology. The coating resists UV, salt air and chemicals, reducing maintenance needs while preserving structural integrity.

Completed in 1987, this bridge is regarded as the flagship bridge of the Sunshine State and remains the longest cable-stayed concrete bridge in the world.

Using LUMIFLON REVE resins on the Sunshine Skyway Bridge provides long-term economic value. The coating reduces the need for frequent repainting, and enhanced corrosion protection safeguards the bridge’s structural integrity, delaying costly repairs and extending its lifespan.

Honshu-Shikoku Bridge Projects (Japan)

Spanning 17 bridges — including the Akashi Straits Bridge — this project proved the durability of LUMIFLON FEVE coatings in harsh marine environments across three expressway routes connecting Japan’s main island, Honshu with Shikoku. These bridges include a variety of structural designs including suspension, cable-stay arch and truss. The project addressed challenges involving UV degradation, sustainability goals and VOC emissions. A primary objective was to extend the lifespan of the bridges while minimizing long-term maintenance costs in Japan’s harsh marine environment.

In 1990, the Japanese government revised the National Specification for Steel Bridge Coatings to include fluoropolymer topcoats tailored to the environment of each bridge. By the end of the project in 1999, approximately 16 bridges featured fluoropolymer topcoats.

Their performance led Japan to mandate FEVE-based systems for all steel bridges by 2005.

This transition underscores the critical role of these coating in protecting critical infrastructures and reducing maintenance costs.

Grand Rapids Blue Bridge (Michigan, USA)

The beloved local landmark, the “Blue Bridge” in Grand Rapids, MI, underwent a much-needed restoration using Tnemec’s Fluoronar coating system, formulated with FEVE fluoropolymer resins. The previous coating had deteriorated, showing signs of chalking, peeling and corrosion on the underlying steel surfaces.

By using a FEVE-based coating system, the bridge now benefits from decades of corrosion resistance, reduced maintenance and sustained visual appeal at lower lifecycle costs.

Skydance Bridge (Oklahoma City, USA)

The Skydance Bridge in Oklahoma City, OK, was constructed using steel tubing coated with Tnemec’s Fluoronar system formulated with LUMIFLON FEVE. The fluoropolymer coating provides exceptional ultraviolet protection for the steel, with a projected life of 30 to 60 years compared to 10 to 20 years for polyurethanes. This longevity reduces the costly repainting cycles and minimizes bridge closures for maintenance.

Building The Future with LUMIFLON FEVE

Today’s bridge designers must balance aesthetics, sustainability and long-term durability. LUMIFLON FEVE resins meet these demands, offering proven protection against corrosion and UV degradation while reducing environmental impact.

While initial costs are higher, the payback is substantial. Over time, bridges using coating systems formulated with LUMIVLON FEVE resins can achieve lifecycle cost savings of 15 to 30% compared to polyurethane systems, which typically require two to three full recoats within the same period.

For more information on how to use powder and liquid LUMIFLON FEVE resins as components for building, structure or bridge coatings, watch our webinar Powder and Liquid FEVE Coatings for Curtail Wall & Infrastructure Applications.

Click here for more information about LUMIFLON FEVE Resins.