Sustainability is now at the forefront of the architectural industry. With carbon emissions from buildings and construction at record highs, the sector is rapidly transitioning to low-carbon solutions. According to this year’s American Institute of Architects’ firm survey, 92% of architectural firms have formal sustainability commitments.

As the architectural, engineering, and construction industries develop sustainable strategies, they are seeking materials, construction methods and operational approaches that minimize environmental impact. While traditional architecture emphasized aesthetics and functionality, contemporary practices prioritize innovative solutions that reduce a building’s ecological footprint while improving resilience and longevity.

Powder coatings, developed to protect and enhance large structures such as buildings and bridges, are gaining popularity for their durability, performance and low carbon footprint, making them ideal for large-scale projects.

Powder Coatings: A Cleaner, Greener Option

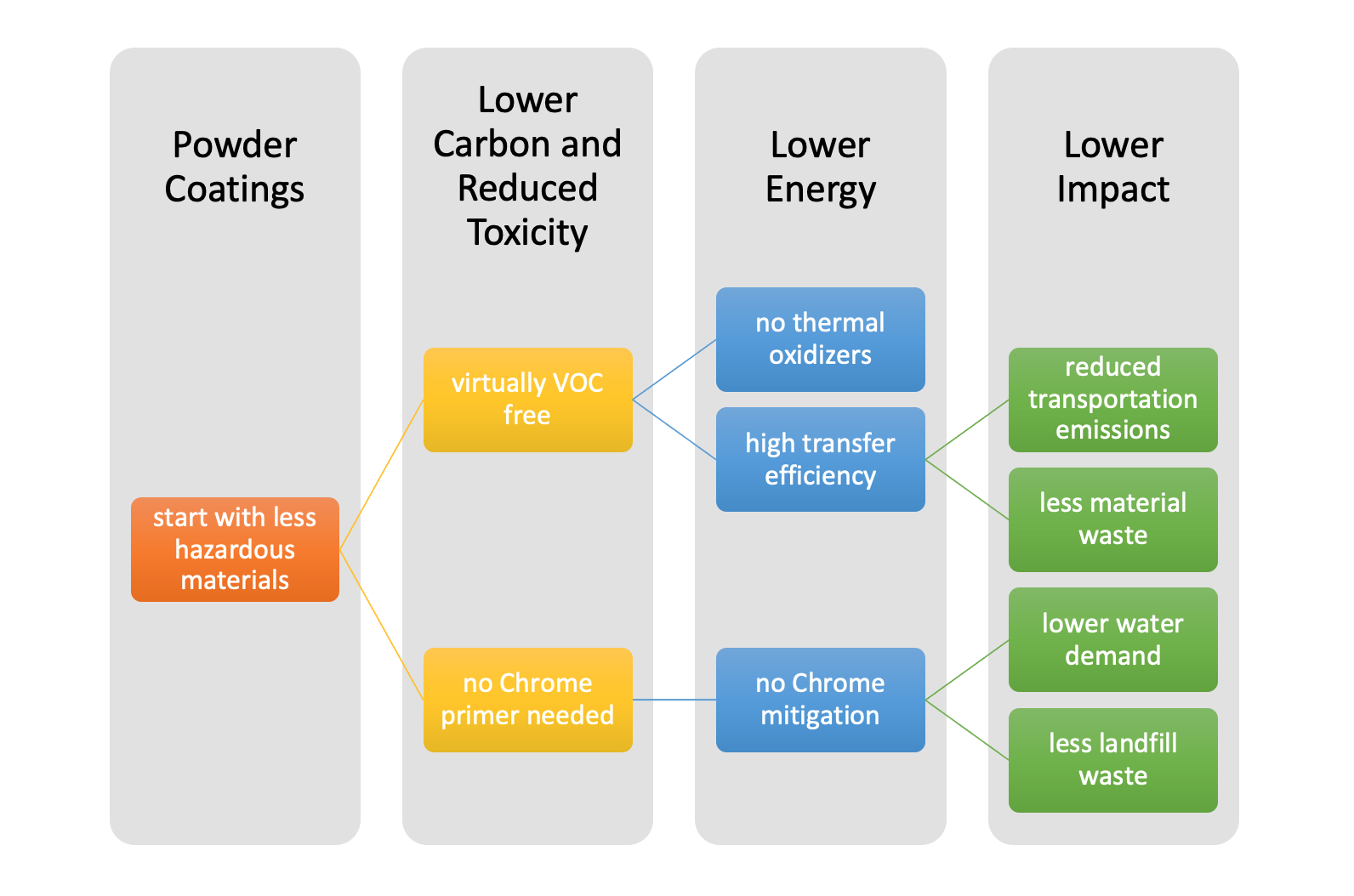

Traditional solution coatings often contain solvents / VOCs (volatile organic compounds) that aid in processing and application and evaporate into the atmosphere during application and curing, contributing to air pollution and smog. FEVE (fluoroethylene vinyl ether) powder coatings are based on solid resins, hence are VOC free, and are melt processed to make the powder coatings, which are then applied using electrostatic methods to coat the parts which are then cured, without the use of any solvents, thus generating significantly less carbon during manufacturing and application.

Applied with an electrostatic gun and conveyed with air, they require no solvents or liquid chemicals to process and apply, reducing water use and waste. High transfer efficiency allows unused powder to be collected and reused—lowering disposal costs and environmental impact.

FEVE-based powder coatings provide decades of durability, reducing the need for recoats and lowering both environmental impact and lifecycle costs, making them a trusted choice where aesthetics and long-term performance are critical.

Supply Chain Benefits

FEVE-based powder coatings are shipped virtually VOC-free, minimizing transportation related VOC, and the lack of solvent eliminates the need for energy-intensive thermal oxidizers required for solvent systems. Many are produced locally, reducing transportation emissions, and packaging is minimized with bulk or recyclable containers.

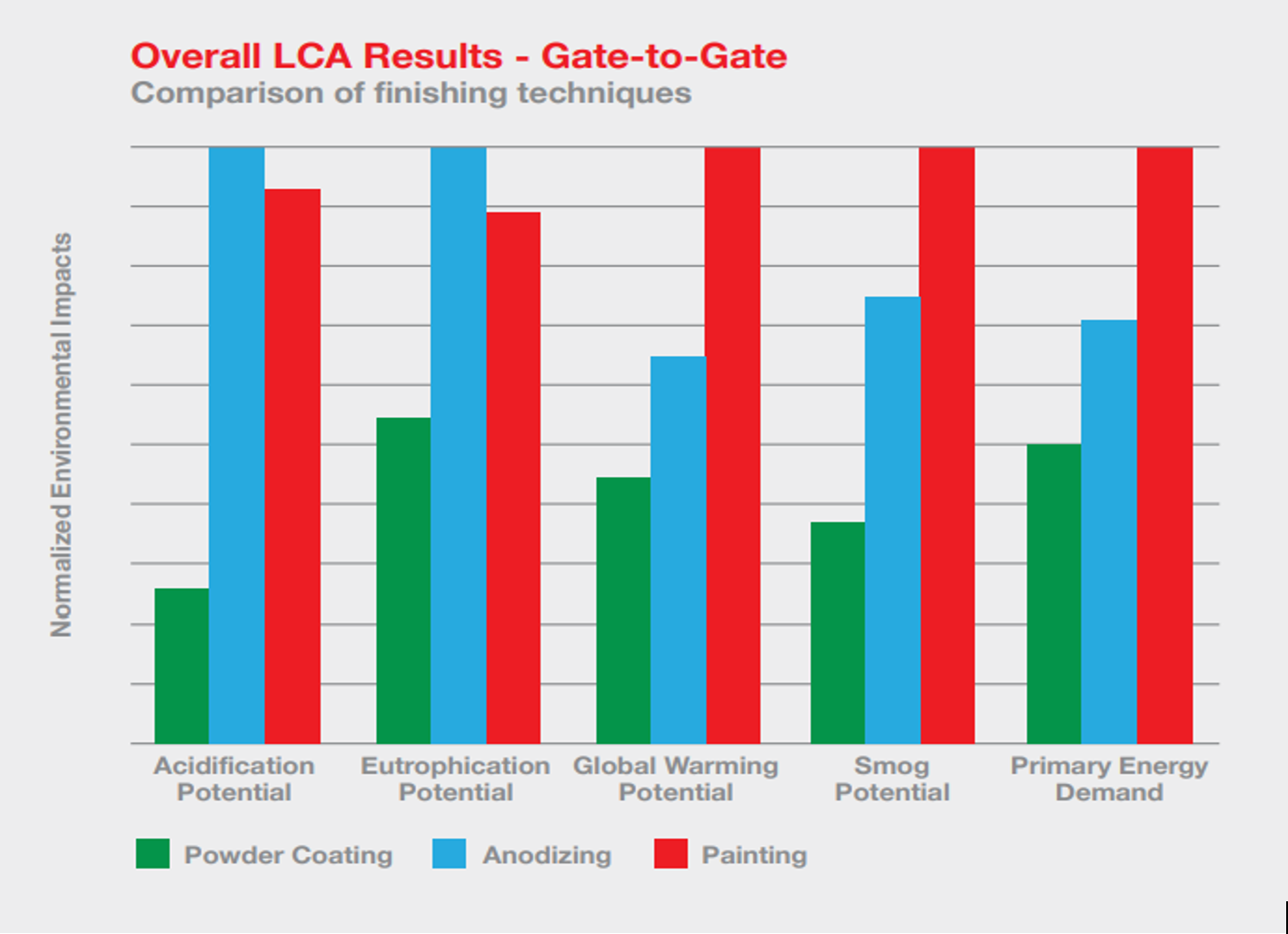

A gate-to-gate life cycle assessment from raw material receipt to shipping shows that powder coatings deliver lower global warming, and smog potential compared to alternatives, while requiring less energy

FEVE Fluoropolymers Outperform Epoxy and Polyester

Powder coatings can be formulated with various base resins, but FEVE-based resins deliver superior outdoor durability over epoxy, polyester and polyurethane. They have been available for more than 30 years, demonstrating superior outdoor performance for UV stability, weather resistance and chemical resistance.

This performance is the result of FEVE’s alternating copolymer structure, which combines fluorocarbon segments for exceptional stability with hydrocarbon segments for strong adhesion and mechanical strength. Amorphous in structure, FEVE resins produce smooth, high-gloss finishes that can either be transparent or rich, vibrant colors, making them ideal for projects requiring long-term protection.

In powder coating applications, OH-functional FEVE resins enable crosslinking to form tough, scratch and mar resistant coatings.

Superior to Solvent Coatings

Liquid coatings, including solvent and water-based paints, were once favored for complex shapes but often generate VOC emissions during application and create solvent waste. In contrast, powder coatings do not contain solvents, are recyclable and when formulated with FEVE resins deliver exceptional UV resistance and longevity, making FEVE based powder coatings increasingly common for exterior architectural metal structures.

FEVE Powder Coating Formulation Example: IFS 500FP

By way of example, Innovative Finishing Solutions a manufacturer of powder coatings, highlights their most durable exterior system IFS 500FP that meets and exceeds AAMA 2605 requirements. The system is a high-performance fluoropolymer powder coating formulated with LUMIFLON® FEVE resin, and is widely used for facades, railings, and other exposed metal structures, offering:

- UV resistance – Retains gloss and finish without fading, chalking, or loss of clarity.

- Corrosion resistance – Protects against moisture, salt, and pollution penetration, hence ideal for coastal and industrial settings.

- Chemical resistance – Resists acid rain, pollution, and industrial chemicals for long-term protection.

Powder coatings based on FEVE resin technology elevate aesthetics and push performance to the highest levels.

Supporting LEED Certification

Green building programs like LEED (Leadership in Energy and Environmental Design) are setting high standards for energy, water and material use. According to the U.S. Green Building Council’s 2025 Market Outlook, LEED certified projects have grown 34% since 2023, with over 156,000 commercial projects certified worldwide.

Powder coatings can contribute to LEED credits, particularly in the Environmental Quality category, by supporting healthier, low-emission building environments.

Building a Sustainable Future

Powder coatings represent the future of sustainable architecture. By adopting FEVE-based coatings, the industry can minimize environmental impact, extend building life and deliver visually striking, high-performance finishes that endure for decades.

AGC Chemicals manufactures LUMIFLON resins, the first solvent soluble fluoropolymer resins designed specifically for coatings thus helping architects and builders achieve both performance and sustainability goals.

Hi, very interesting info. But what about the PFAs in the formulation of this FEVE-Based Powder Coatings?

Thanks!