LUMIFLON solid resins offer the same outstanding weatherability and durability as our other LUMIFLON grades. These products, which include LF-200F and LF-916F resins, can be used to formulate coatings that meet the latest air pollution regulations for volatile organic compounds (VOCs) by incorporating the appropriate exempt solvents. LUMIFLON solid resins are used to make coatings for applications including architectural, aerospace and industrial maintenance.

Our LF-710F solid resin grade was developed specifically for use in powder coating applications. It’s high Tg provides the thermal properties in the base resin necessary for the production and handling of powders. The resin is combined with other components of the powder coating formulation, including curatives, pigments and additives. Powder coatings made with the LF710F resin offer excellent aesthetics and the same outstanding weatherability as other LUMIFLON liquid coatings.

- Enables ultra-weatherable fluorourethane powder coatings.

- Powder coatings can be manufactured using standard processing equipment.

- Produces a full gloss range—from matte to high gloss.

- Supports a variety of finishes, including clear coats, custom colors and textures.

- Is processed at room temperature, hence it requires no expensive cryogenic grinding.

Markets

- Architectural coatings, both factory and field applied

- Coil coatings

- Industrial maintenance

- Plastic coatings

- Automotive

- Aerospace

- Field repairs

LF200F and L916F Solid Resins Typical Properties

| grade | LF200F | LF916F |

|---|---|---|

| Characteristics | solid resins for use with tailored solvent choice including exempt solvents for low VOC coatings | |

| Typical Application | factory spray or field application | |

| Markets | architecture, industrial maintenance, transportation, aerospace, alternative energy | |

| Substrates | metal including steel and aluminum, plastic, fiberglass, concrete, wood, composites | |

| Molecular Weight | moderate | low |

| OH Value, mg KOH/g polymer | 52 | 101 |

| Solvent | none as supplied; may be dissolved in various solvents | |

LF200F and L916F Downloads

Product Data Sheets

LF710F Typical Properties

| Grade | LF710F |

|---|---|

| Characteristics | solid flake resin for powder coatings |

| Typical Application | thermoset powder coating using electrostatic spray |

| Markets | architecture, transportation |

| Substrates | metal including steel and aluminum |

| Molecular Weight | moderate |

| OH Value, mg KOH/g polymer | 51 |

LF710F Recommended Powder Processing Equipment

| Process | Powder Equipment | Example |

|---|---|---|

| Mixing | Common mixer | Henschel, Mixaco |

| Extruding | All type of extruder | Single, Twin Screw & Planetary |

| Grinding | Various mills | ACM, Turbo, Jet |

| Classification | Common classifiers | Mesh,Air classifier |

LF710F Powder Application Method

| Coating Equipment | Yes / No |

|---|---|

| Electrostatic gun | Yes |

| Fluidized dipping | Yes |

| Tribomatic gun | No |

Weathering of LF710F

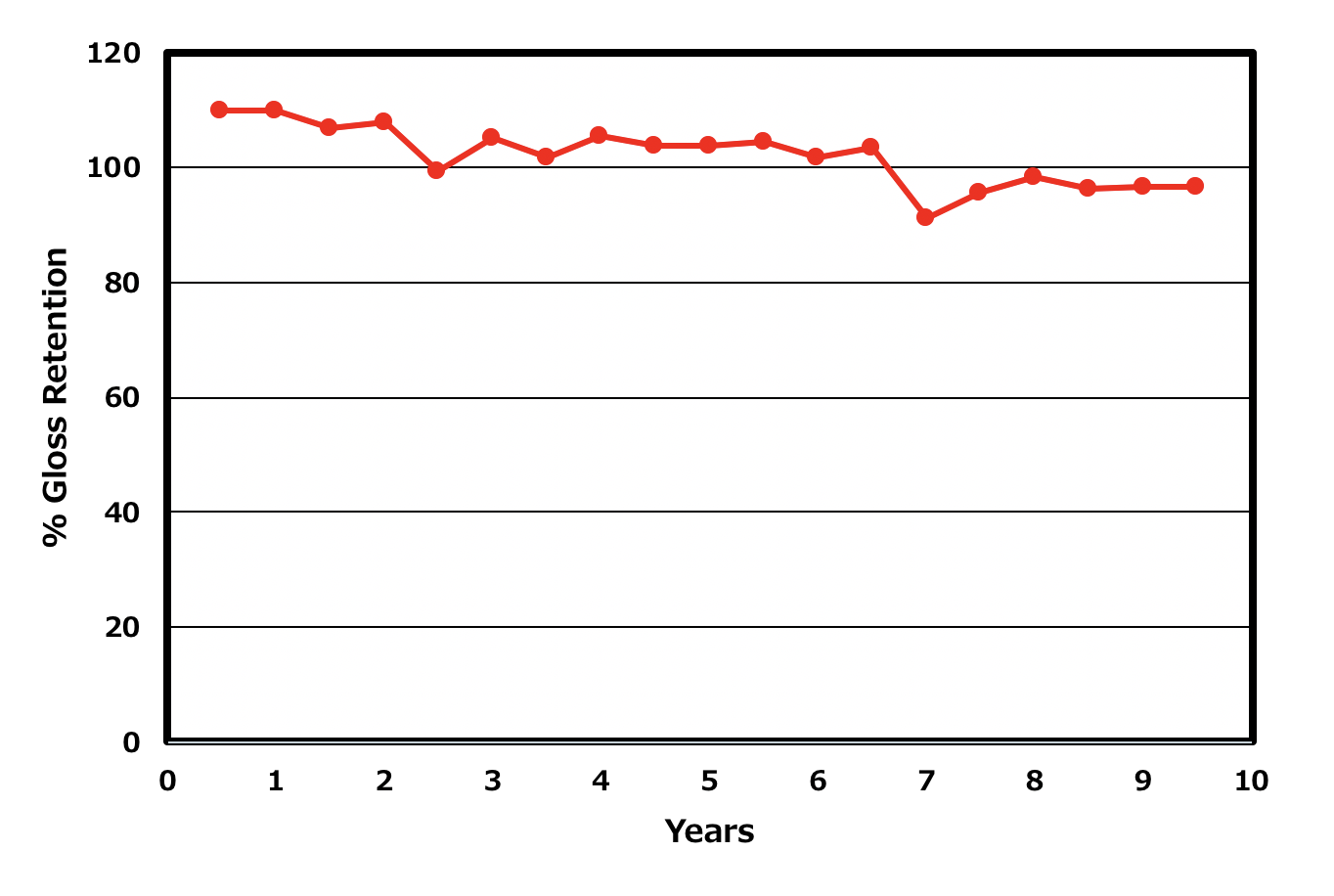

S. Florida: LUMIFLON LF710F Clear Powder Coating

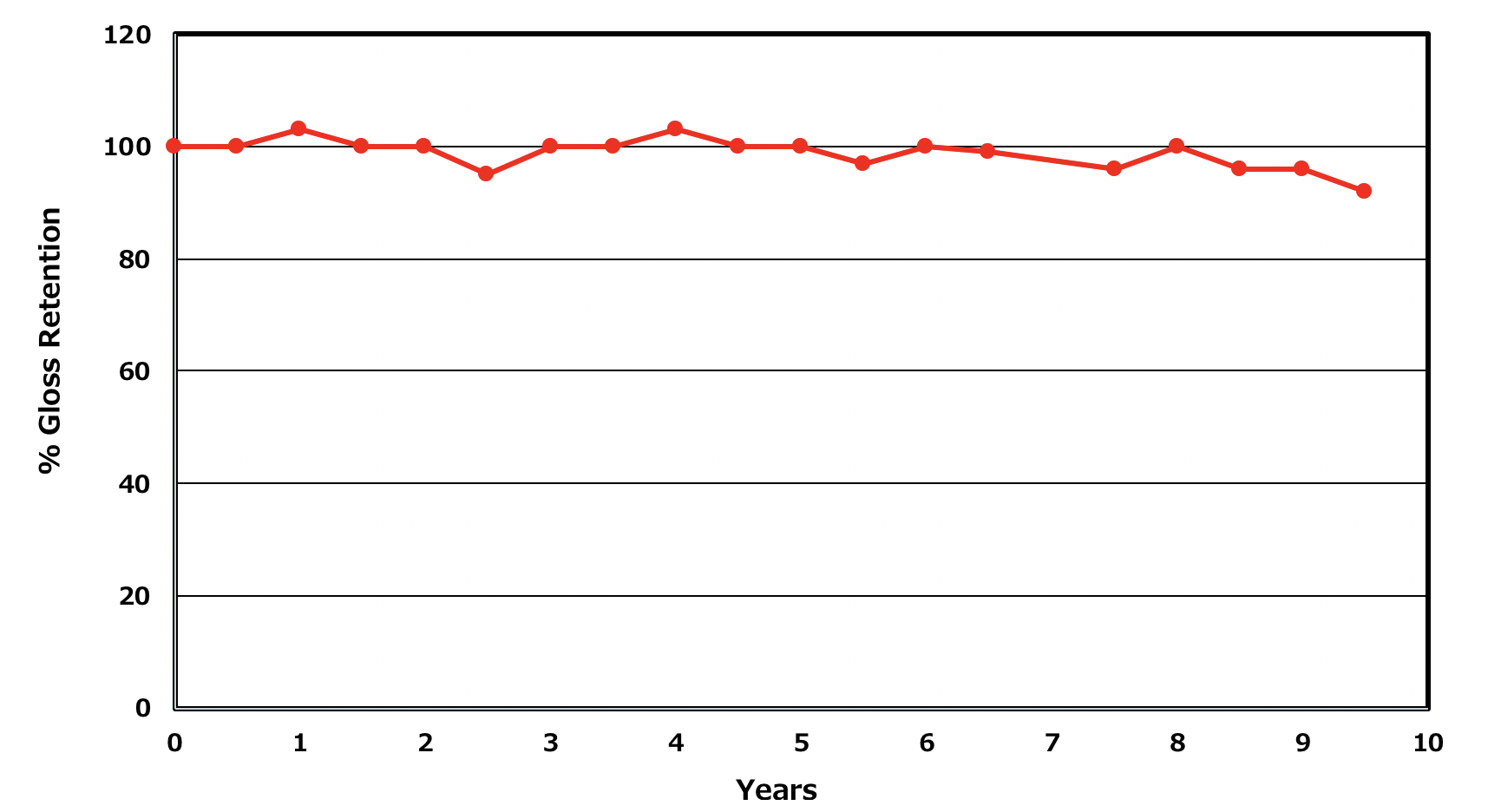

S. Florida: LUMIFLON LF710F White Powder Coating

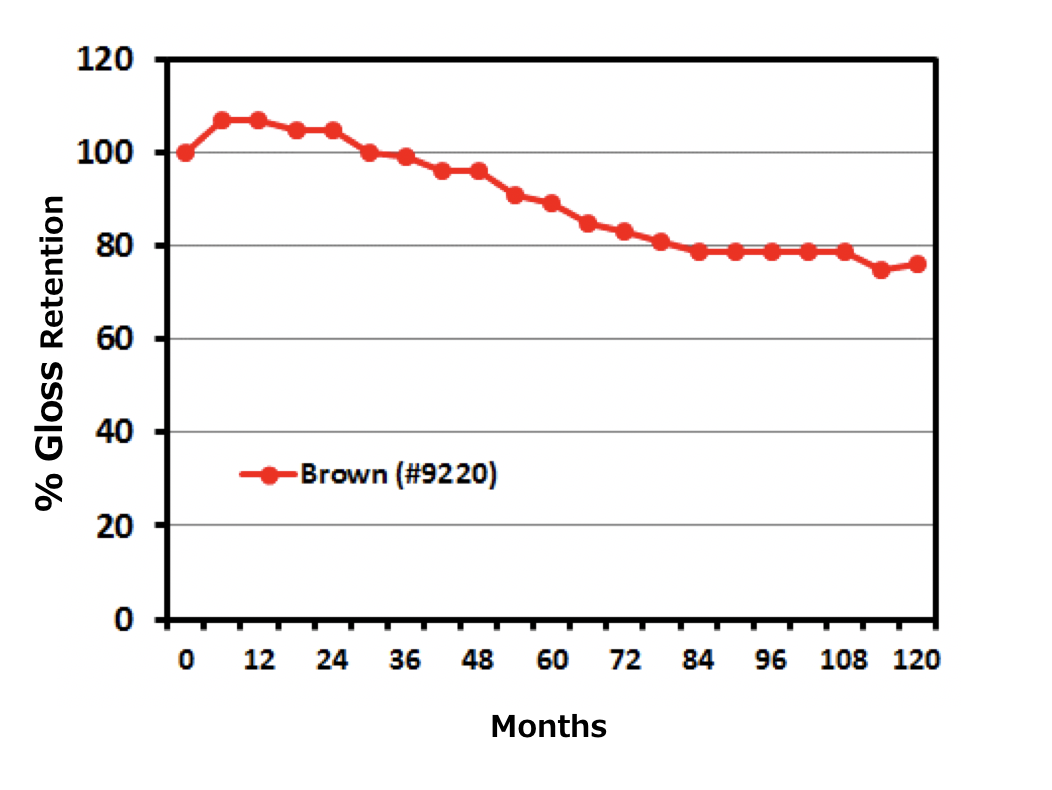

S. Florida: LUMIFLON LF710F Brown Powder Coating

LF710F Downloads

LF710F Data Sheets