Industry insiders know that, from buildings and bridges to water towers and automobiles, LUMIFLON-based coatings look great. But they look even better when cold, hard data comparing LUMIFLON with high-performance polyesters and other competitors are collected from tests and studies conducted in laboratories, simulators and harsh, real-world environments. The results confirm what you see with your own eyes every time you look at an attractive, long-lasting LUMIFLON coating. All over the world; LUMIFLON outperforms the competition.

Advantages of FEVE Based Coatings

- Ambient or elevated temperature cure – field or shop applied coatings

- Solvent soluble – clean crisp colors and a wide gloss range

- Versatile – solvent grade, solid, water based and powder coating resins offered

- OH functional – polyurethane chemistry, use standard paint equipment

- Fluoropolymer segments-ultra-weatherable and corrosion resistant

- Longer life cycle – up to 60 years

Weathering of LUMIFLON

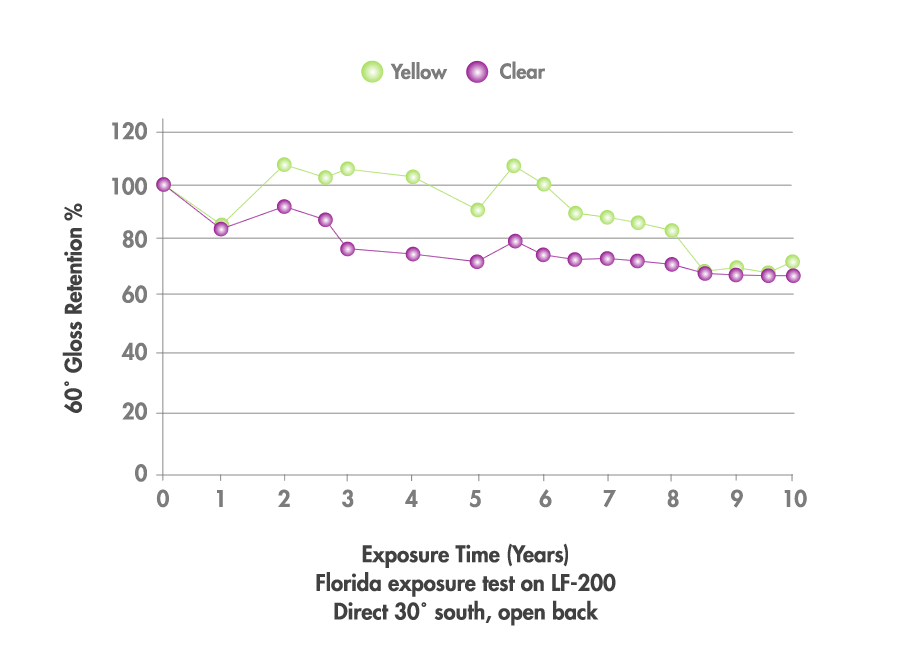

Natural Exposure Test on LUMIFLON

Miami, Florida (ASTMG7)

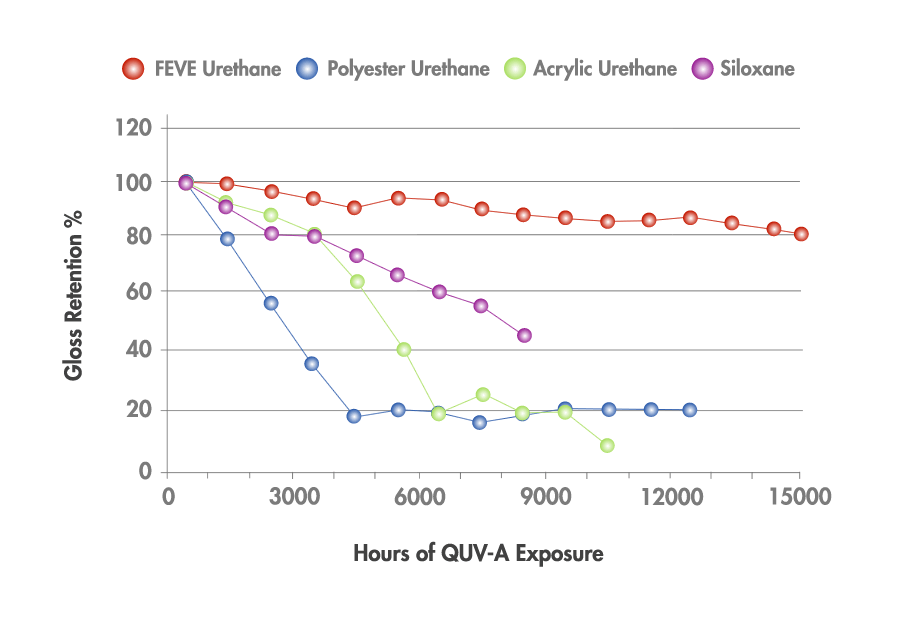

FEVE Resin Topcoats Accelerated Weathering

QUV-A (ASTM D4587)

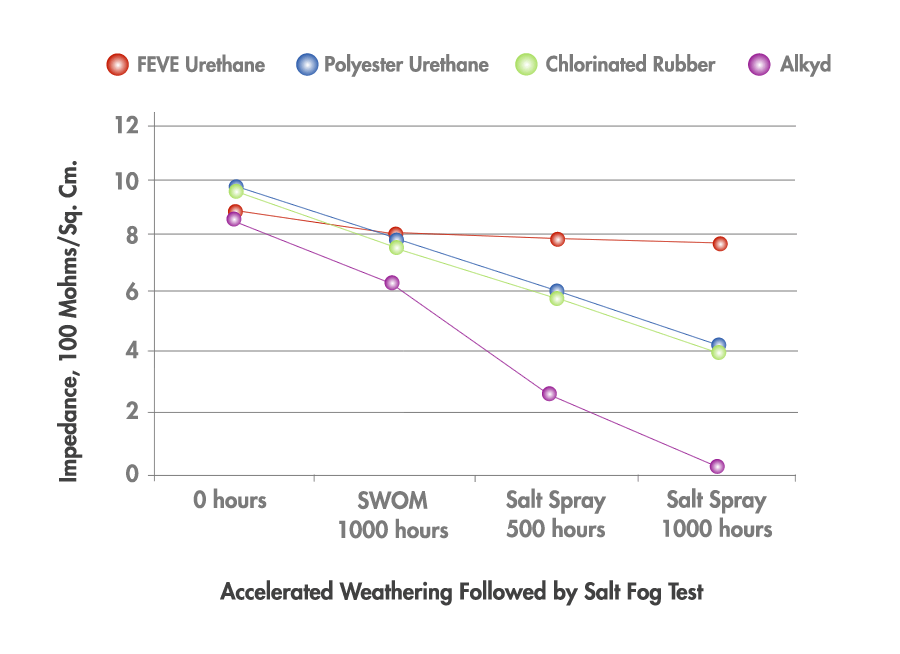

Electrochemical Impedance Spectroscopy

*The closer the line is to horizontal, the better corrosion resistance