There are a whole host of benefits to the utilization of an FEVE resin over a pvdf. These benefits include aesthetic-based benefits, application-based benefits, and sustainability benefits. FEVE (fluoroethylene vinyl ether) was developed to address the shortcomings with traditional fluoropolymer resins like PVDF, they are manufactured by copolymerization of a fluoroethylene monomer with a vinyl ether monomer.

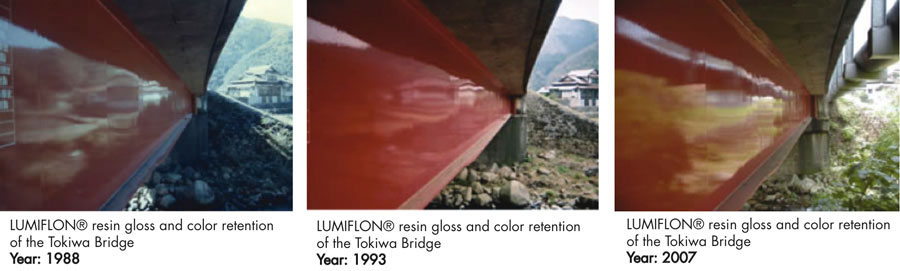

In terms of an FEVE resin's aesthetic-based benefits, the FEVE chemistry yields coatings with high gloss levels upwards of 90 degrees (measured at a 60o angle). With a broader range of gloss, FEVE coatings produce both a brighter color palette and color retention versus PVDF. Gloss, flexibility, hardness, adhesion, pigment compatibility, and transparency can all be modified by changing vinyl ether monomers.

PVDF is typically applied as a coil coating, which requires processing at high temperatures in a protective plant setting. FEVE resins are curable at ambient temperatures. This allows for the coatings to be applied outside of a factory for exterior applications such as bridge repairs. It allows applicators the flexibility of both shop or field application.

Boasting a number of sustainable qualities, FEVE resins have low permeability to oxygen, water and chloride, which offers high degradation resistance when exposed to airborne pollutants and other environmental conditions. Additionally, an FEVE resin is easily repairable and is often used as a restorative product to repair previously degraded PVDF applications.

The product is extremely versatile with hundreds of thousands of applications across the world. FEVE resin is used for a variety of architectural applications, often as a protective topcoat to ensure the longevity of materials like steel, aluminum, fiber cement, and metal composite. The product also has a proven track record in its use on roofs, doors, canopies, fences, poles, signs, concrete, glass and even plastic substrates.

Categories Technical

Hi there,

I would like to have the technical data for FEVE for use as external wall Cladding/Facades.

My understanding is that FEVE perform better or similar to PVdF in terms of color retention and exposure to UV lights attacks.

Your information is highly appreciated.

Thank you